DR250 Bass Guitar/PA Speaker

Last Update: 19 July 2005

Back to Lou's Homepage

One of my friends told me that his son, Adam, had recently taken up bass guitar. Adam wanted some advice on what kind of speakers he should use. Pro sound isn't my thing, but I was fairly certain that the DIY world had something out there that was at least as good as the bargain retail offerings.

I did quite a bit of research, and finally wound up on Bill Fitzmaurice's site. Bill has quite a few folded horn deisgns. I've been intrigued with horns since the 80's when one of my roommates had a pair of Klipsch LaScala's. The idea of an inexpensive, highly efficient bass box made a lot of sense, especially since I had a young, able bodied assistant! After browsing, exchanging emails, I bought plans to Bill's DR250.

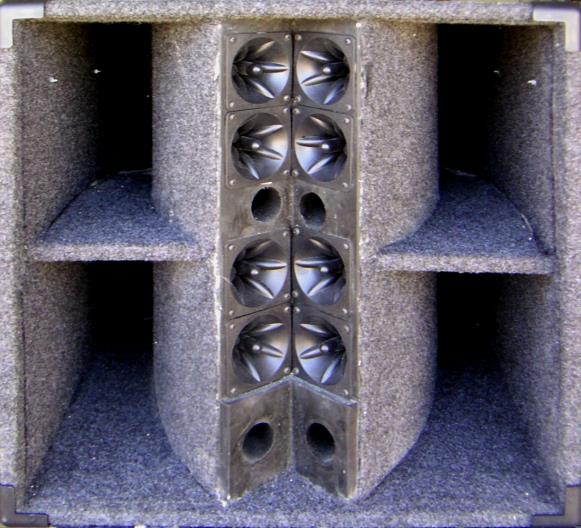

The DR250 uses a 10" prosound woofer with an optional tweeter array. After looking through the recommended drivers, I chose an Eminence Beta 10 with 8 piezo tweeters. Construction of the box (as I did it) uses 1/2" baltic birch plywood, 1/8" poplar "bending" plywood, and 3/8" bending luan plywood. We probably had 40 hours into the construction.

The final form is a very impressive speaker for the $170 in components and wood. This is a very articulate PA monitor that could probably run off of 10 watt toy amp. We tried it with one channel of my cheapie 50 watt shop receiver. Neighbors came by to see if they were left out of the party!

As predicted, some equalizing would be necessary for "flat" response. Sounds much better from 20-40 feet away than it does up close. The crossfired piezos are surprisingly good. Somewhat harsh & sibilant up close, but very listenable at longer distances (especially for under $2 each!) It does a great job on vocals & piano. MUCH cleaner than the average DJ rig.

Last, (but not least) is the way cool factor. Adam is looking forward showing up with a one of kind box, that he helped build. I'm looking forward to some future income from his gigs down the road.